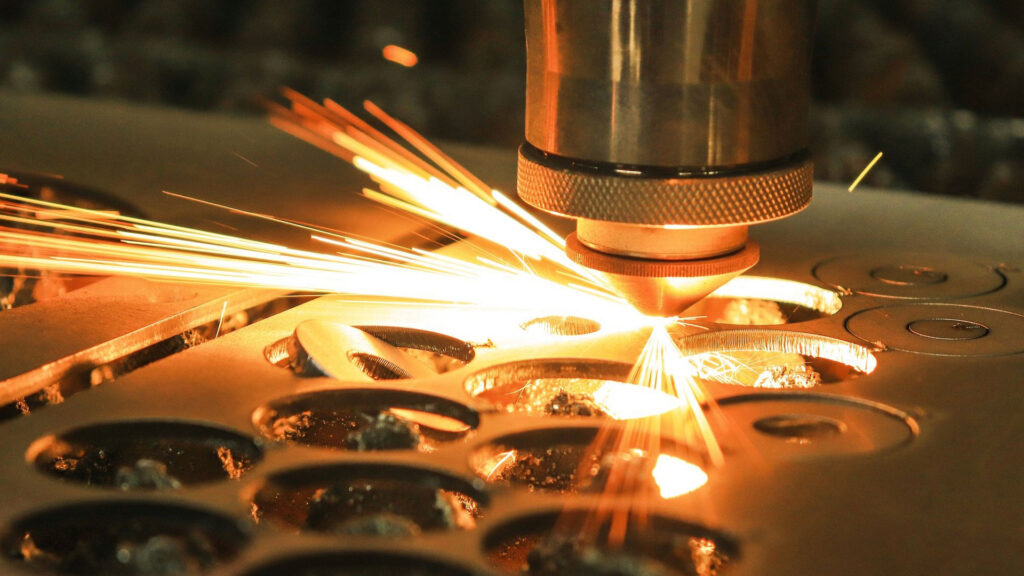

Laser cutting uses a laser in slicing materials. An assisting gas is used to protect the surface from high temperature and oxidation reactions. Some of the advantages of laser cutting and forming include:

- High precision and accuracy cuts

Laser cutting and forming incorporate a tint and powerful laser to deliver a focused beam of light to the material it’s cutting through with high precision. The laser evaporates and melts the material with extreme accuracy, making them the best choice. For this reason, laser cutting and forming are the most preferred in spaces such as the aerospace industry.

- Low lead times with no need to modify or replace tooling

Another perk of using laser cutting and forming is that the tools in use are economical, even for limited-run projects. That is because it does not use any that must be modified or custom-built for your project.

All you need to do is a laser cutter, material to cut, and a schematic that can get loaded into the computer. That reduces the overall costs compared to traditional manufacturing and tooling. Also, laser cutting and forming tools have few mechanical moving parts. That helps to minimize operations and maintenance costs.

- Handle most jobs of any complexity

There is almost no job that a laser cutting and forming machine cannot do. A high-powered one can work on any material section results in minimal distortion and warping to the area getting worked on. A laser cutting and forming equipment can get used to effortlessly and swiftly create high-complex geometries with its excellent tolerance levels.

Laser cutting and forming can almost get used in any material, from ferrous metals such as aluminum, brass, copper. And other materials, including wood, textiles, plastics, and components.

- Less waste

Another perk of using laser cutting and forming is that due to its accuracy and precision in cutting, it utilizes a high percentage of your sheet material. That maximizes the number of usable parts and components from any given material.

Again, this results in minimized costs for your projects and efficiency. Little time is required to swap new material sheets, and little raw material gets wasted during the cutting process.

- Low power consumption

The laser used in cutting materials uses energy, but the laser cutter has no moving parts. Unlike other machines with presses and other cutting tools that use high amounts of energy to do their work, laser cutting will not. That decreases your overall costs while minimizing its impact on the environment.

That disused, how do you decide on the ideal laser cutting and forming machine for your fabrication?

- Choose the type of machine.

There are varying types of laser cutting and forming machines available for the job. For instance, there is the CNC laser cutter that automates your work. And allows for intricate and accurate work. And the desktop laser cutter is ideal for DIY lovers and small businesses. There are also laser cutting and forming equipment ideal for cutting specialized objects.

- Check the speed

The speed of the laser cutting and forming machine matters a lot. Before purchasing one, ensure to check its speed and gauge how long it takes you to complete a project. Pay close attention to the specifications so that you can make the right choice.

- Align it with your requirements

Another way to pick the ideal laser cutting and forming machine is by evaluating your requirement. Always select something that can effortlessly do this.

Look at the workpiece and metal you are going to cut with it. The best machine will work in line with your requirements.

Also, consider a laser cutting and forming machine that is compatible with your workshop. Check its weight and size. Avoid a bulky one if you’re doing less complicated work since it will take more of your space and hinder movement.

- Power consumption

Another factor to look at is the power consumption of the laser cutting and forming machine. See the effect your choice of machine will have on your electrical bill. Also, an efficient machine will use less power, while the latter makes you use a lot of time, energy, andok[ waste power consumption.

- Check if you can maintain it.

Finally, any machine requires maintenance and upkeep at some point. While buying a laser cutting and forming machine, assess how often you need to do maintenance and get spare parts. One that is economical will require less of this. Also, choosing a high-quality laser cutting and forming machine means it will require little maintenance since all the parts are of high quality.

Leave a Reply